Tips from the Field

Agronomy Update | Pre-Harvest Crop Management

Timely pre-harvest management decisions are key to ensuring harvestability, managing green weed pressure, and preserving seed quality. Below is a side-by-side comparison of the most common pre-harvest products for canola and cereals. Each has a different fit depending on harvest timing, weed pressure, and desiccation needs. Reminder that weather conditions (like frost or cold temps) can impact efficacy of applied products.

| PRODUCT | BENEFITS | WHEN TO APPLY | CONSIDERATIONS | PHI | |

|---|---|---|---|---|---|

| Canola | Cereals | ||||

| Crop Dry Down | |||||

| Diquat Brands | Contact activity with quick dry down - can be applied on cloudy days | 90%+ Seed Colour Change | Not Labeled | Higher water volumes required, staging of crop is vital as premature application will result in yield loss. Check label for adjuvant requirements. | None |

| Weed Control Only | |||||

| Glyphosate | Registered for pre-harvest weed control | 50-60% Seed Colour Change | Hard Dough Stage | Not a crop desiccant, do not apply to crops grown for seed production, consult grain buyers prior to application. | Apply 7-14 days before harvest to ensure best weed control |

| Dry Down and Weed Control | |||||

| Heat LQ | Provides crop dry down and weed control | 80% Seed Colour Change | Hard Dough Stage | Can be mixed with glyphosate, consult with grain buyers prior to application | 2-3 days, crop specific, consult label |

Canola

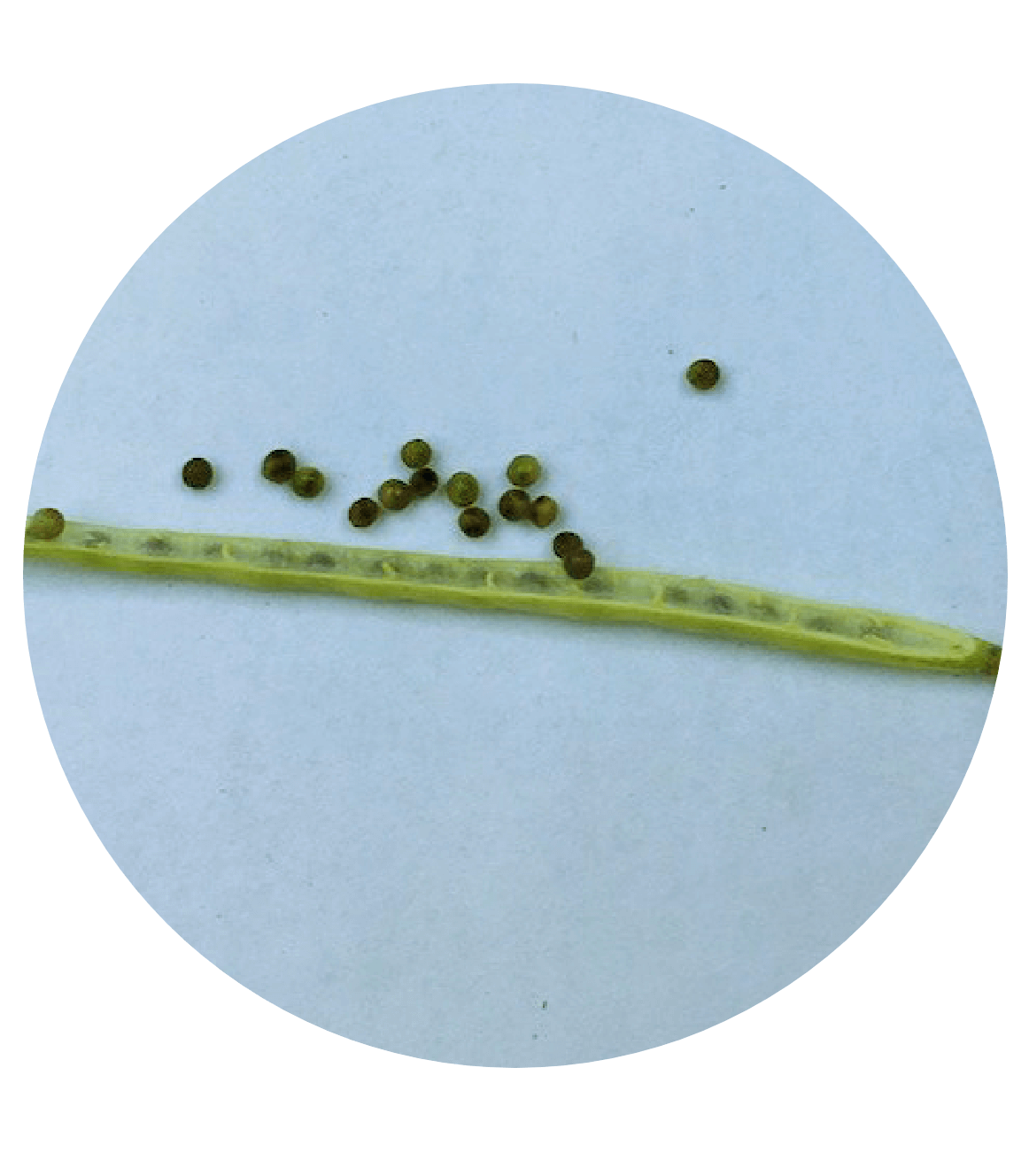

How to determine 60% Seed Colour change

Divide the main stem into thirds and assess seed colour inside pods from each third

Green but are firm when rolled in fingers

Mostly broken with some speckling and mottling

All seeds are brown to black

Cereals

Before making a pre-harvest application, check with the grain buyer to ensure the crop treated pre-harvest with glyphosate will be accepted. If a pre-harvest aid is approved for use, wait until the least mature part of the field reaches 30% grain moisture content prior to an application. Heat LQ and Glyphosate are not registered as desiccants in cereals but are registered as a pre-harvest weed control treatment.

Target Hard Dough Stage

This stage can be determined by pressing your thumbnail into the kernel. An indent will remain on the kernel if at the hard dough stage. The spongy stage prior to hard dough will not allow the indent to remain. The thumbnail test can be used to determine hard dough stage in barley, oats, and wheat.

Consult Keep it Clean (https://keepitclean.ca/) for any questions related to maximum residue limits (MRLs) and market acceptance. Keep it Clean recommends to only apply pesticides that are registered for use on your crop in Canada, are acceptable to both domestic and export customers, and won't create trade concerns.

Want this resource as a PDF?